|

Optimization benchmark problem for water supply pump

scheduling

Summary

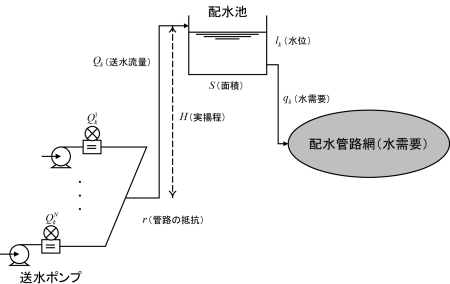

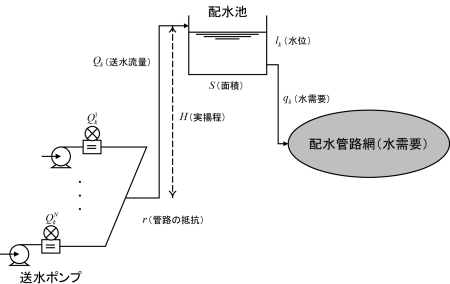

The water supply pump scheduling problem is formulated to determine a water supply pump operational schedule so that the number of pump on-off switching and total of power consumption are minimized with satisfying a water demand and keeping the water level of the distribution reservoir within a given range in the water supply process as shown in Fig. 1.

This benchmark problem provides the 24 time operation scheduling problem with 6 pumps.

The specific formulation is given in the references [1] and [3].

Fig. 1: Water supply process [1] (the characters in the figure are written in Japanese) Class and scale

- Class: Discrete nonlinear two objective optimization problem

- Number of decision variables: 24 (Continuous: 0, Discrete: 24)

- Number of inequality constraints: 73 (Linear: 24, Nonlinear: 49)

- Number of equality constraints: 0 (Linear: 0, Nonlinear: 0)

Known Feasible Solutions (OFV is objective function value. Sol. is solution.)

| Method |

OFV

(Pareto solution) |

Constraint violations |

Ref. |

Reporter |

Sol. |

| Total |

Tolerance |

| A* Search Algorithm |

f1 = 2, f2 = 3417.83764

f1 = 3, f2 = 3306.95791

f1 = 4, f2 = 3277.06181

f1 = 6, f2 = 3251.44448

f1 = 8, f2 = 3224.37637

|

0 |

0 |

[2] |

Y. Ueno, et al. |

Sol.† |

| Random Search × ε-constraint Method |

f1 = 3, f2 = 3365.29934

f1 = 4, f2 = 3334.67785

f1 = 5, f2 = 3281.34058

f1 = 6, f2 = 3277.06181

f1 = 7, f2 = 3254.27247

f1 = 8, f2 = 3224.37637

|

0 |

1.0 × 10-10 |

[1] |

T. Okamoto |

Sol.† |

†Decompress the obtained file. Replace the decompressed text files by "P2_solution_y.txt" in the source code.

Source code

P2.zip (C/C++) — See "Readme.txt" in order to know how to use.

References

| [1] |

Investigating R&D committee on new development of computational intelligence techniques and their applications to industrial systems: "Optimization benchmark problems for industrial applications", IEEJ Tech. Rep., No. 1287, Section 3.3 (2013) [in Japanese] |

| [2] |

Y. Ueno and K. Mori: "Optimizing pump operation scheduling for water supply systems", Proc. of IEEE Int. Conf. on System Science and Engineering 2014, pp. 171–174 (2014) |

| [3] |

K. Yokokawa, T. Okamoto, A. Kawagoe, Y. Ueno, and K. Mori: "Formulation and solutions for daily operation scheduling problem of water supply pump", Proc. of the first IEEJ International Workshop on Sensing, Actuation, and Motion Control (SAMCON2015), IS1-4 (2015) |

Change log

- June 5th, 2015: The bibliographical data of the reference [3] is updated.

- Dec. 3rd, 2014: English page is released.

- Sept. 18th, 2014: A new solution is added to Known Feasible Solutions.

- June 3rd, 2014: Tolerance of constraint violations can be read from the external file.

- Mar. 13th, 2014: Parameters can be read from the external file. Destructor is modified.

- Nov. 7th, 2013: The source code is released.

|

|

|